Vibrator & Bracket Specifications

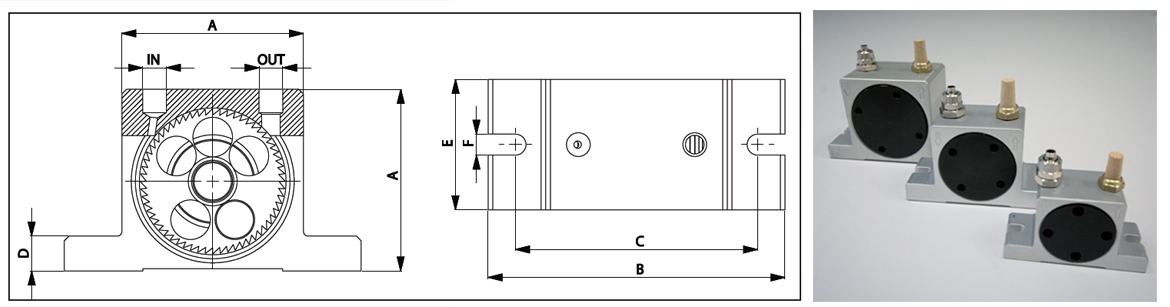

Vibrator

Details

- Light weight at 5.8kg

- No tools required

- 5mm m/s C Channel 350 x 100 x 50mm

- Safety Tether

- Universal bolt pattern to suit Oli OT36

- Hardened steel handles quick & easy action

- Simple lock and release action in seconds

- Placement with one hand

- Lock into position with the other hand

- For Vibration placement please refer to your job drawings

Features

| DUTY CICLE | CONTINUOUS |

| WORKING PRESSURE | FROM 2 BAR TO 6 BAR (FROM 29 PSI TO 87 PSI) |

| PNEUMATIC CIRCUIT | FILTER+FLOW CONTROL VALVE+LUBRIFICATION+3/2 WAYS VALVE |

| AIR SUPPLY QUALITY | CLASS 5.4.1. |

| WORKING TEMPERATURE | FROM -20°C TO 120°C (FROM -4°F TO 248°F) |

| MAX NOISE LEVEL | <90 dB(A) |

| TECHNOLOGY | TURBINE VIBRATION - HIGH FREQUENCY AND CENTRIFUGAL FORCE |

| ATEX | II 2D CT(X) / II 2G CT(X) |

| MATERIAL | ALUMINUM BODY |

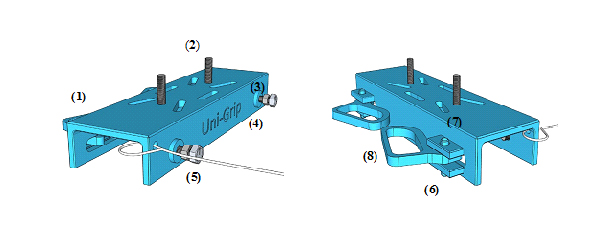

Uni-Grip Bracket

1. Main steel C channel Uni-Grip body

2. Slots to suit OT36 high frequency vibrator

3. High tensile threaded cup set screw

4. Lock nut for set screw

5. Safety tether cable

6. Handle supports

7. Hardened roll pins

8. High tensile ergo handles

Guidelines for use

- Working conditions to be safe & free from obstructions

- Understand concrete to be used

- Formwork should be clean, free from debris, treated with appropriate release agent & leak proof

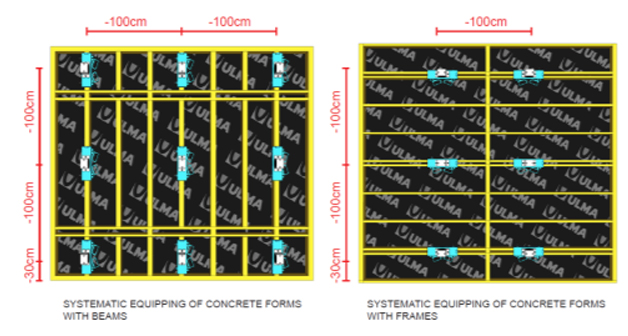

- Placement of vibrators to be 1.0 – 1.2m apart in both horizontal & vertical positions

- Vibrators to be placed approx. 300mm – 400mm from edge of form

- Mount Uni-grip to fixing point to allow good transmission of vibrators amplitude

- Vibrators should only be attached directly to stiffening profiles (never directly to FW skin)

Guidelines for use cont.

Running time

• Compaction time 1-5 min per layer

• Start vibrators once concrete fill commenced

• Concrete layer height: max. 50cm

• Heavy reinforcing used – additional minute vibration time

• Wooden formwork used – add 1-2 min

• Vibrators must be moved up the form in line with pour process

Advice for fastening

• Tighten fastening system firmly

• Always fasten safety tether

• Check rotation is in upwards motion

Equipping a concrete form

• Equip concrete forms in horizontal rows

• Compaction only – switch on row closest to concrete layer being poured

• Fully equipped with ext. vibrators or ext. vibrators can be relocated form bottom to top (in line with pour)

• 2 rows of vibrators recommended for 2nd cast

Factors to consider when determining vibration times

• Slump & MPA of concrete

• Type of formwork – steel, ply (> time required due to absorption of vibration)

• Aggregate size (smaller aggregate = finer vibration required)

• Time between pours – check setting times

Why vibrate concrete ?

• To ensure consistency of concrete density

• To prevent optical layering

• To ensure even amalgamation of layers

• To remove excessive air from fresh concrete & improve surface finish

• If wall thickness > 400mm – important to place vibrators on both sides of formwork